Intralogistics conveyor systems

The world of intralogistics conveyor systems is all about speed, efficiency and quality.

Kersten produces curved parts for various conveyor systems. So too for QuickMove's latest and most innovative system.

Read the article below:

Innovation through collaboration: QuickMOVE and Kersten

QuickMOVE and Kersten join forces for the latest generation of conveyor systems.

The successful collaboration between QuickMOVE and Kersten shows how two experts join forces to deliver an innovative and high-quality solution to the logistics challenges of the future.

Evolution: a new generation of transport systems

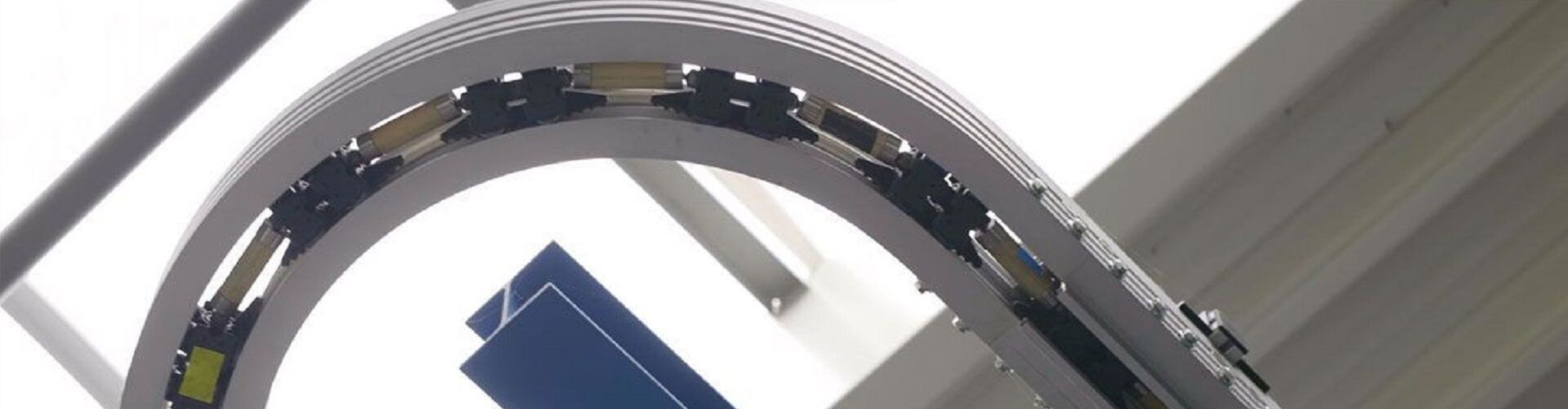

QuickMOVE, known for its expertise in flexible intralogistics systems, offers customised solutions that are fully tailored to customers' specific requirements. ‘Our latest product is QuickMOVE Evolution, a transport system that can be fully adapted to the customer's desired routing thanks to its modular design,’ explains Peter Heppelmann, QuickMOVE's technical director. A key element of these conveyor systems are the curved sections. The system can not only transport horizontally, but also vertically and with tight bends. ‘We have been working with Kersten for years as a partner for the curved sections of our conveyor systems and we have continued this pleasant cooperation for QuickMOVE Evolution.’

Curved parts: Kersten's role

The bends in a conveyor system allow flexible configuration and adaptation of routing, optimising the use of available space and enabling the system to function even in narrow or densely built-up areas.

The production of these curved segments requires specific knowledge and expertise in aluminium bending. This is why QuickMOVE entered into a partnership with Kersten, the specialist in bending technology. Manuel Hartmann, Sales Manager at Kersten GmbH, further explains: ‘Already during the development phase, we advised on the ideal design of the profile cross-section so that the profile maintains its functionalities even when bent and meets high quality standards.’ Heppelmann added: ‘We take Kersten's advice to heart. After all, perfect shape in curves is crucial for the overall performance and efficiency of our system. It prevents unnecessary wear and tear and contributes to smooth operation.’

Innovation through collaboration: a successful synergy

The successful collaboration leads to a new generation of transport systems. Manuel Hartmann of Kersten: ‘The cooperation with QuickMOVE is very pleasant and based on quality and trust. The company is characterised by its innovative strength, solution orientation and high quality standards - values that are also particularly appreciated at Kersten. Together, we combine our expertise to develop optimal intra-logistical solutions.’

About QuickMOVE

QuickMOVE offers flexible 3D conveyor systems for intralogistics applications in the mobility, mechanical engineering and pharmaceutical sectors. QuickMOVE develops, plans and designs conveyor systems based on clients' needs and requirements.

More information: www.quick-move.de

About Kersten

Kersten specialises in bending technology and the production of bent sub-assemblies and structures in steel and aluminium. Aluminium is bent in special non-ferrous production facilities according to client specifications, 5-axis machined. surface and/or heat-treated and assembled.

More information: www.kerstengroup.com